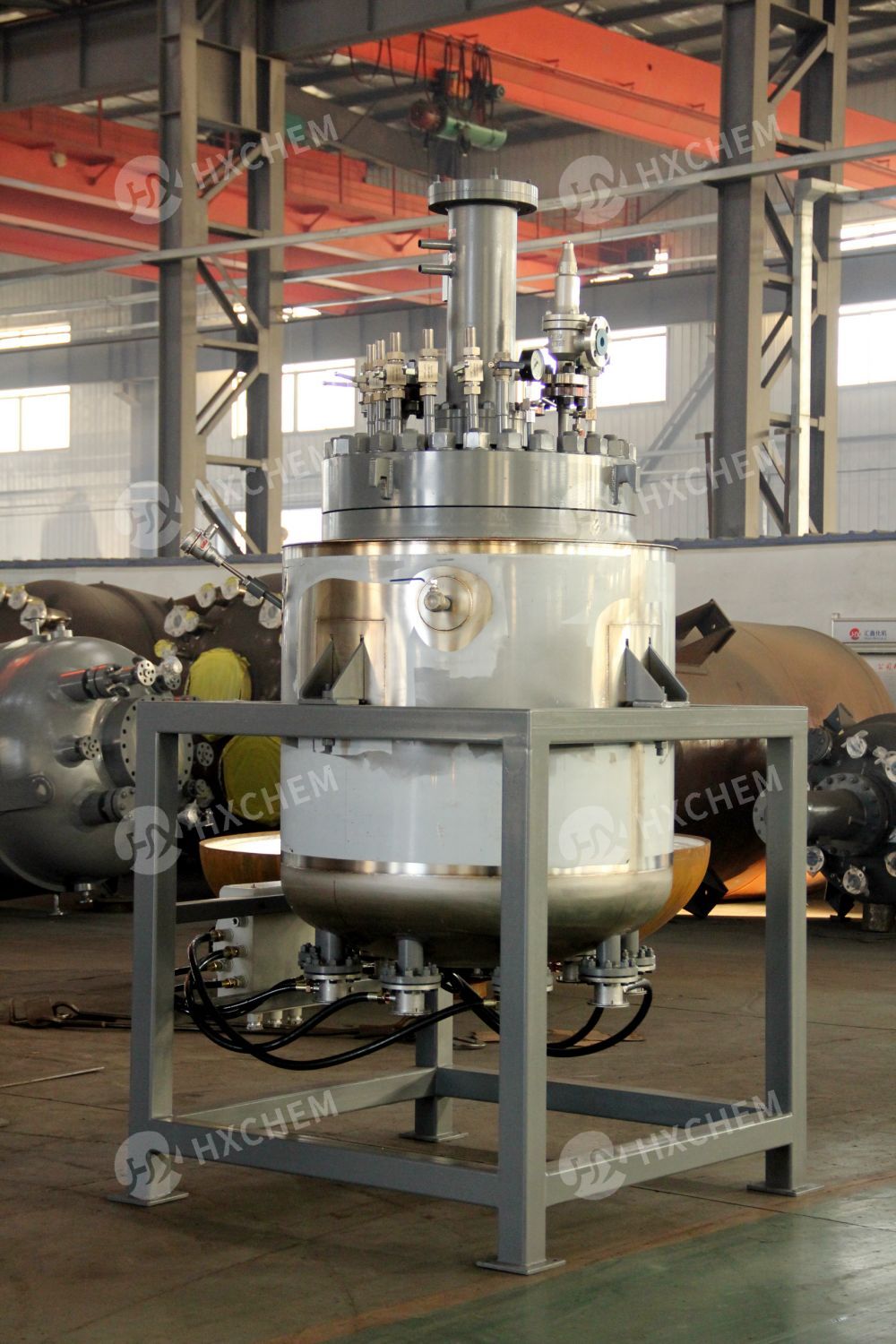

Autoklaf tekanan kacau yang dipanaskan 1000 liter

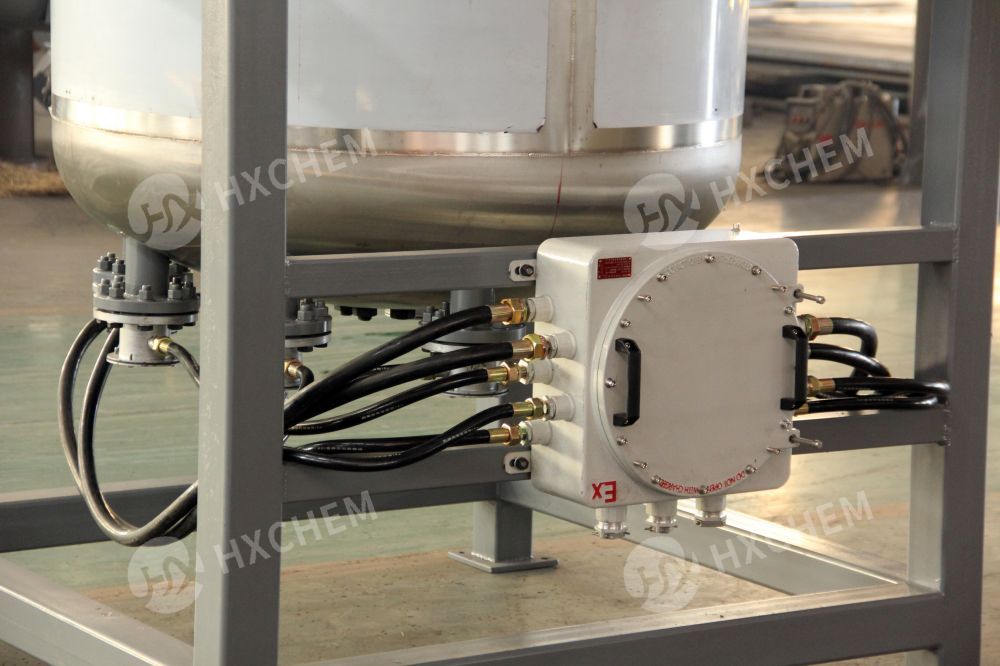

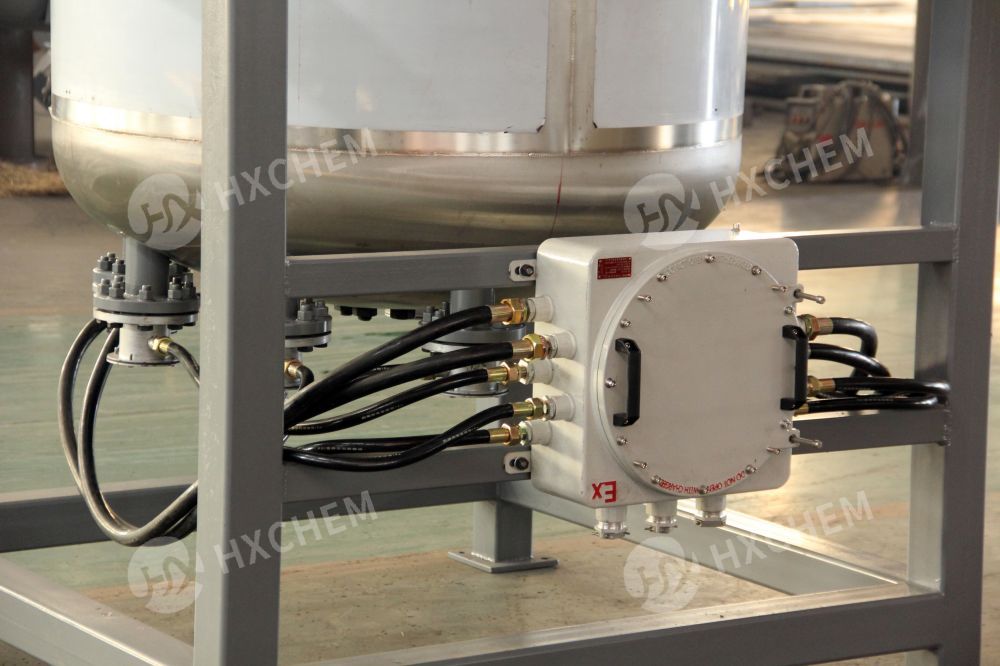

Jaket 1000liter autoklaf tekanan kacau yang dipanaskan/ Pelapisan keluli tahan karat dengan reaktor kimia pemanasan elektrik kalis letupan/ Dilengkapi dengan pemacu gandingan magnetik dan injap tekanan, injap keselamatan, dsb.

- HXCHEM

- China

- 75 hari

- 100set/bulan

Butiran

Autoklaf tekanan kacau yang dipanaskan 1000 liter

pengenalan

Produk siri ini adalah autoklaf tekanan kacau yang dipanaskan 1000liter yang diperbuat daripada keluli tahan karat, termasuk reaktor tekanan tinggi perintis, sistem pemanasan, sistem penyejukan dan sistem kawalan, yang digunakan terutamanya untuk proses tindak balas perintis, ia merupakan proses pembangunan yang penting daripada eksperimen kepada pengeluaran perindustrian . Autoklaf skala perintis menggunakan meterai kacau magnetik, yang sesuai untuk tindak balas kimia dengan keperluan pengedap yang tinggi, toksik dan mudah meletup.

SPESIFIKASI REAKTOR 1000LITER

Isipadu: 1000liter

Tekanan maksimum: 40bar

Suhu maksimum: 250℃

Bahan: SS304, SS316, Hastelloy C276, pelapisan SS321

Jenis pemanasan: Pemanasan elektrik, Pemanasan minyak

Bukti letupan: Ya

Pengacau: Baling-baling, Dayung, Turbin, Aruhan Gas, disesuaikan

Jenis berjaket: Gegelung konvensional atau Limpet

Penebat: Ya

PENYESUAIAN HXCHEM SEPERTI FELO:

Autoklaf tekanan tinggi

Reaktor penghidrogenan perintis

Reaktor penghidrogenan

Reaktor perintis

Sistem Reaktor Perintis

Reaktor skala juruterbang

Reaktor kimia perintis

50liter, 100liter, 200liter, 500liter reaktor tekanan tinggi

Spesifikasi standard reaktor tekanan pandu GSH

| GSH-50 | ||||

| 50 | ||||

100bar standard, -0.1-250 bar disesuaikan | ||||

SS304 atau SS316 bahagian basah, aloi lain (Titanium, Hastelloy, keluli Dupleks, dll.) | ||||

0~350 sesuaikan berdasarkan suhu kendalian. | ||||

| 0-500 | ||||

| 1.5 | ||||

Mengikut suhu kerja | ||||

Pemanasan elektrik standard (Minyak terma, wap, pemanasan inframerah jauh tersedia) | ||||

Penutup rata atau penutup bebibir elips | ||||

Baling-baling, dayung, sauh, lingkaran, turbin, jenis induksi gas, dsb | ||||

Penyejukan lingkaran menyejukkan dengan air penyejuk | ||||

Menyahcas dari bawah atau atas. | ||||

Paparan dan kawalan suhu PID, ketepatan±1 ℃; Paparan kelajuan kacau; Paparan masa operasi; Pemanasan voltan dan paparan semasa; Skrin sentuh pilihan. | ||||

Tolok tekanan, Pelabuhan injap keselamatan; Temp. pelabuhan pengukur; Pelabuhan gas dan cecair; Tiub celup; Pelabuhan bolong; Port pengecasan pepejal; Salur masuk dan penyejuk gegelung penyejuk; | ||||

Nota:Parameter standard di atas adalah untuk rujukan sahaja. Proses yang berbeza mempunyai pemilihan munasabah mereka sendiri, bukan fungsi yang lebih lengkap, lebih baik.

Struktur, spesifikasi, saiz muncung dan orientasi perlu dikonfirmasikan selepas berkomunikasi dengan kami.